Inductive Voltage Transformer EOF

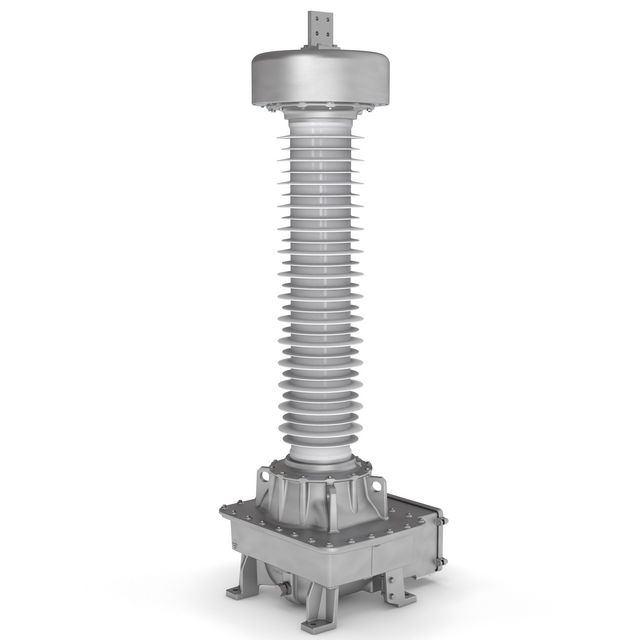

Oil-paper insulated inductive voltage transformers type EOF are used in high voltage networks within the 24-245 kV range. They transform high voltage into standardised values for meters, measuring and protection devices.

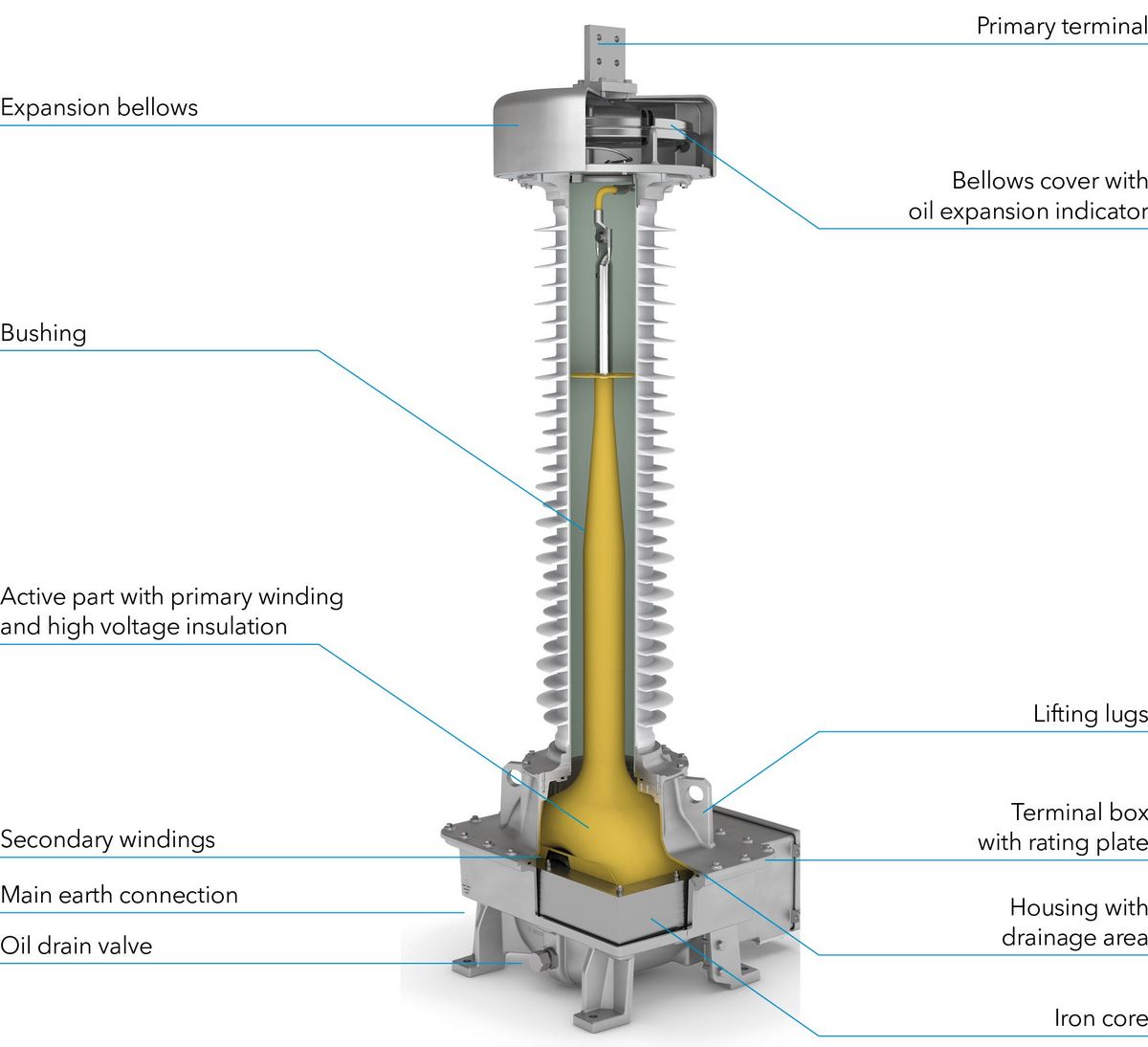

The active part of the voltage transformer is located in the foot housing. The high voltage insulation is implemented in oil-paper technology. To achieve this, a high quality PCB-free mineral oil is used. The fine graded bushing is inside the insulator.

The expansion system is located in the head of the voltage transformer. This unit acts as volume compensation for the oil in case of temperature variations. For voltage transformers of 24-72 kV, a highly flexible, temperature-resistant membrane made from fluoroelastomers (VITON®) is used. Voltage transformers >72 kV have an expansion cell made of stainless steel. The oil level is indicated by a mechanical system in the window of the bellows cover.

All metal housings and flanges are made from a special aluminium alloy. These parts can be colour coated on request.

All voltage transformers have either a high-quality porcelain or a high-grade silicone composite insulator. Different creepage distances are available according to the different pollution classes, as specified in the standards.

The hermetic sealed housing protects the oil-paper insulation against atmospheric influences.

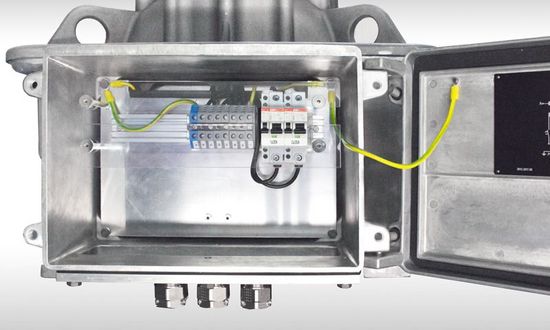

The generously sized terminal box has a cover which can be opened sidewards. This allows easy connection of the secondary cables. The terminal box has a flange without holes by default. Cable glands, circuit diagram and individual safety instructions can be preinstalled on request.

Features

- Protection of the secondary winding from transient overvoltages in the high-voltage network through capacitively coupled shielding

- Protection against occurring ferroresonance through low operating inductance in the iron core

- High operating safety as there are no active parts in the insulator

- Minimum oil volume through optimised design

Specifications and Downloads

Technical Specifications

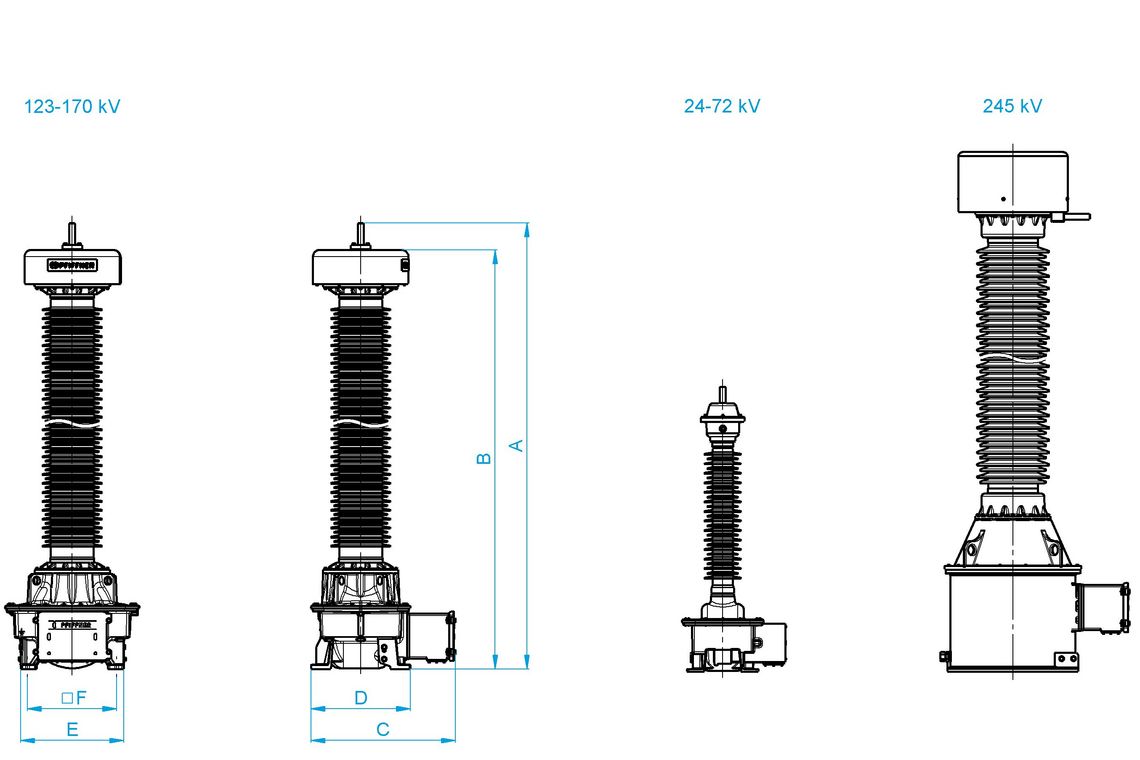

Dimensions

Technical data

Type EOF | 24 | 36 | 72 | 123 | 145 | 170 | 245 | |

| Standard | IEC / IEEE | |||||||

| Highest voltage for equipment | kV | 24 | 36 | 72.5 | 123 | 145 | 170 | 245 |

| Rated power-frequency withstand voltage | kV | 50 | 70 | 140 | 230 | 275 | 325 | 460 |

| Rated lightning impulse withstand voltage | kV | 125 | 170 | 325 | 550 | 650 | 750 | 1050 |

| Frequency | Hz | 16.7 / 50 / 60 | ||||||

| Accuracy class | 0.1-3; 3P; 6P | |||||||

| Rated thermal limiting output VT part | VA | ≤ 1500 | ≤ 3000 | |||||

| Max. simultaneous burden (cl. 0.2) | VA | 200 | 300 | |||||

| Max. number windings | 5 | |||||||

Type EOF | 24 | 36 | 72 | 123 | 145 | 170 | 245 | ||

| Height of unit* | A | mm | 1107 | 1107 | 1430 | 2116 | 2392 | 2581 | 3507 |

| Height to primary terminal* | B | mm | 1027 | 1027 | 1350 | 1976 | 2252 | 2441 | 3206 |

| Depth of unit including terminal box | C | mm | 526 | 526 | 526 | 710 | 710 | 730 | 938 |

| Depth of unit base | D | mm | 360 | 360 | 360 | 500 | 500 | 500 | 660 |

| Width of unit base | E | mm | 360 | 360 | 360 | 520 | 520 | 520 | 660 |

| Distance between screw holes at base | F | mm | 310 | 310 | 310 | 450 | 450 | 450 | 600 |

| Min. creepage distance* |

| mm | 950 | 950 | 1860 | 3080 | 3900 | 4394 | 6160 |

| Approximate weight* |

| kg | 115 | 115 | 125 | 305 | 330 | 335 | 350 |

*with standard composite silicone insulator, creepage distance 25 mm/kV